Shipping Container Issue Highlights Need to Address Infrastructure

LUBBOCK, TX – As Congress and the White House continue to spar over what is and is not needed for infrastructure investments in the U.S., supply chain concerns continue to mount.

Right now, CNBC reports 140 ships in West Coast ports with 83 more arriving in the next 24 hours and 63 more expected in the next 30 days. Though the costs of shipping from China to the United States are down 20 percent compared to last month, the cost is not the real culprit in the shipping delays.

The supply crisis is fueled by a lack of container chassis’, a shortage of truck drivers, and an abundance of empty containers. Officials at the Port of Long Beach (the second largest in the country) project 78 percent of containers being loaded for export are empty which means roughly one in every four containers are loaded with exports from the U.S. (24,044 loaded vs. 105,174 empties).

To move cargo quicker, the $1.5 billion Long Beach Container Terminal project at Middle Harbor has concluded and the final phase included a nearly one-mile long concrete wharf capable of servicing three ships at once

Still, the average turnaround time for the two largest ports in the U.S. (Los Angeles and Long Beach), according to Bloomberg, almost doubled this year to 6.4 days from 3.6 in 2017 to 2019, and with ships anchored for an average of 12 days, there’s no real relief in sight.

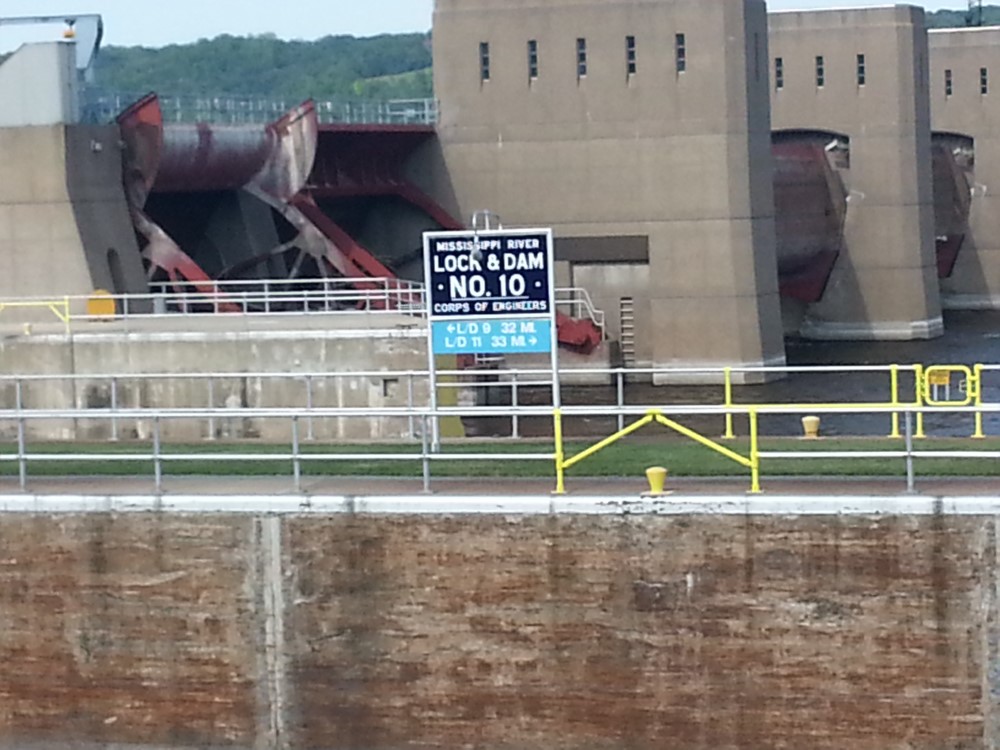

Though unrelated, bulk shipments of grain may be delayed as well. With the majority of the nation’s grain and oilseed exports shipping through the Gulf of Mexico, problems on the Mississippi River have slowed some early-season barge traffic. Also, Cargill’s Texas facility, best known for loading wheat and sorghum for transport, is now loading soybean shipments that have been rerouted from Louisiana to Houston due to damage from Hurricane Ida.

(SOURCE: All Ag News)